- Stationary Crushing Plant

- Mobile Crushing Plant

- Sand Making Plant

- Vibro Sand Plant

Hourly Capacity: 30-50 TPH

Maximum Feeding Size: 13.4″-16.7″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 100 TPH

Maximum Feeding Size: 20″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 200 TPH

Maximum Feeding Size: 24.8″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 300 TPH

Maximum Feeding Size: 29.5″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 30-50 TPH

Maximum Feeding Size: 13.4″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 50-80 TPH

Maximum Feeding Size: 16.7″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 100-150 TPH

Maximum Feeding Size: 20″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 200-250 TPH

Maximum Feeding Size: 29.5″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Model: Mobile Sand Making Plant

Hourly Capacity: Custom

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Model: Movable

Hourly Capacity: Custom

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Model: Stationary

Hourly Capacity: Custom

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Description

As the infrastructure construction in the Philippines develops faster and faster. The demand for high-quality sand and gravel aggregates continues to grow. Investing in a good crushing production line is a good choice for you. SMAT crushing plant can crush various raw materials, such as cobblestone, limestone, granite, basalt, marble, quartzite, iron ore, etc. Choose SMAT and we will provide you with a one-to-one annual fee solution based on your needs.

Hot Sale

Stationary Type 100-200TPH

Compact and efficient, ideal for small-scale projects. Handles up to 100 tons/hour, offering reliable performance for primary and secondary crushing.

Stationary Type 500TPH

High-capacity solution for large operations. Processes up to 500 tons/hour, featuring robust construction and advanced automation for optimal productivity.

Mobile Jaw Crusher

Our Mobile Jaw Crusher is engineered to deliver exceptional crushing performance, portability, and reliability. Designed for mining, quarrying, and recycling operations, this machine is the ultimate choice for achieving maximum productivity and superior material quality on any job site.

Mobile Cone Crusher

Our Mobile Cone Crusher is designed to deliver exceptional crushing power, portability, and reliability. With advanced technology and robust engineering, this machine is the ultimate choice for achieving high productivity and superior material quality on the go.

Related Cases

Please check more about SMAT concrete batching plant case in the Philippines

SMAT Partner

SMAT Crusher Machine Introduction

Jaw Crusher

With simple and firm structure, reliable operation, easy maintenance and service, and relatively low costs in production and construction, the SMAT jaw crusher is still widely used in coarse, medium, and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building materials, electricity, transportation, and other industries.

01

Cone Crusher

SMAT cone crusher is a kind of stone crusher machine applied for metallurgy, building, road construction, chemical engineering, etc. It is suitable for medium and fine crushing with the features of a high crushing ratio, high efficiency, low energy consumption, and uniform particle size.

02

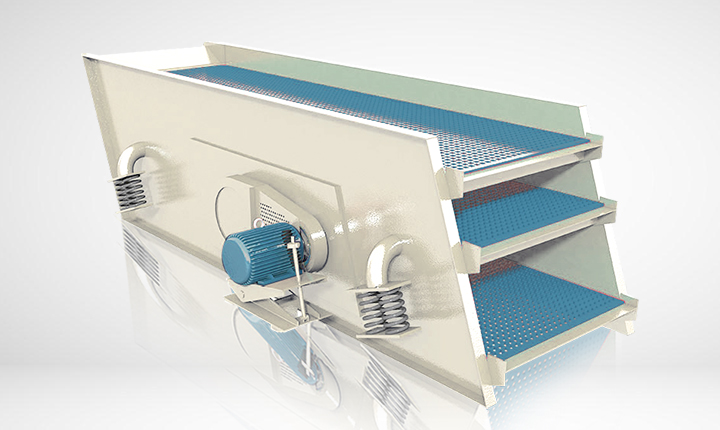

Vibrating Screen

SMAT vibrating screen has high structural strength, simple maintenance, and long service life. Suitable for heavy, medium, and fine screening and other screening operations. The sieving machine is ideal for handling the products after primary and secondary crushing, as well as for inspection screening in the process and final product screening.

03

Sand Making Machine

As the high-end construction market in the Philippines demands higher quality finished sand, the addition of sand makers makes the finished product more detailed. If the size and shape of the produced materials cannot meet your requirements, you can consider adding a sand-making machine to crush and shape the materials again. The commonly used equipment at this stage is a sand-making machine.

04

SMAT Promise

Advantage

SMAT Crushing Plant in the Philippines

You May Need

SMAT provides various crushing plants and machines for quarry projects in the Philippines, feel free to contact the SMAT team.

Specification

Jaw Crusher Specification

| Model | PE400×600 | PE500×750 | PE600×900 | PE750×1060 | PE900×1200 |

| Size of Feeder Opening (mm) | 400×600 | 500×750 | 600×900 | 750×1060 | 900×1200 |

| Max. Feeding Size (mm) | 340 | 425 | 500 | 630 | 750 |

| Adjustment range (mm) | 40-100 | 50-100 | 65-160 | 80-140 | 95-165 |

| Processing capacity (t/h) | 16-60 | 40-110 | 50-180 | 110-320 | 220-450 |

| Over all dimension (mm) | 1730×1730×1630 | 1980×2080×1870 | 2190×2206×2300 | 2660×2430×2800 | 3380x2870x3330 |

| Motor Power (kw) | 30 | 55 | 55 | 110 | 110 |

| Weight (t) | 7 | 12 | 17 | 29 | 52 |

Service

- SMAT's local office is located in Quezon City, Manila.

- Filipino engineers team are always available for on-site installation guidance, commissioning, and training services.

- SMAT provides regular visiting to clients sites, thus can promptly correct improper operations.

- SMAT accepts Peso Payments.

- Adequate stock of original spare parts to ensure the smooth operation of the project.

- Free customized product appearance color and Logo, provide ODM support.

- 7*24 hours online free consulting service, including quotation, 2-3 sets of program design, AutoCAD & 3D drawings, and site planning.