We provide fixed crushing stations in various specifications and configurations, which can be customized according to your specific needs. These devices are highly stable and reliable and can operate stably for a long time, providing continuous support for your production line.

SMAT stationary concrete batching plants require professional installation at a fixed location. But do not worry, we will provide support by on-site technical training. Stationary batching plants are more suitable for long-term large-scale projects with high weighing accuracy and high concrete quality.

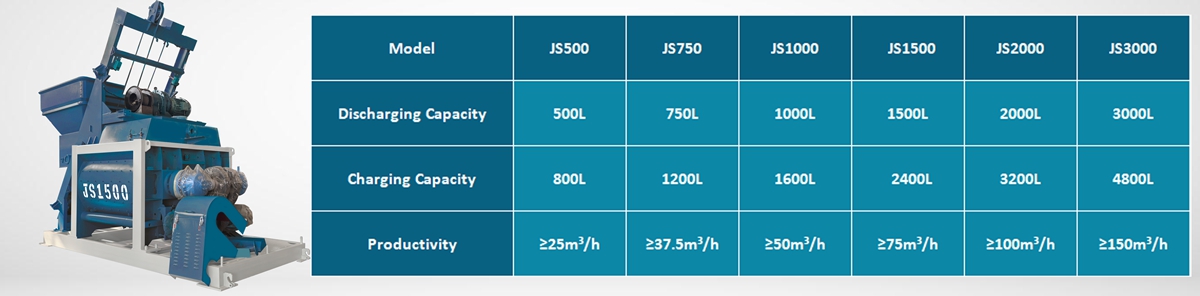

Model: JS750

Discharging Capacity: 750L

Charging Capacity: 1200L

Productivity: ≥37.5m³/h

Model: JS1000

Discharging Capacity:1000L

Charging Capacity: 1600L

Productivity: ≥50m³/h

Model: JZC Series

Charging Capacity: 250L-500L

Productivity: 7-20m³/h

Aggregates: 60mm

Model: JZM Series

Charging Capacity: 800-1200L

Productivity: 18-22.5m³/h

Aggregates: 60mm

SMAT Concrete Batching Plant in the Philippine:

SMAT concrete batching plant mainly consists of five main systems: mixer, material weighing system, conveying system, storage system, and control system. If you want to know more about the basic components, SMAT will introduce them to you as follows.

SMAT concrete batching plant introduces advanced mixing technology and is equipped with an efficient mixing system to ensure uniform and stable quality of concrete. It has high production efficiency, strong mixing ability, and strong flexibility.

01

Equipped with an intelligent management system to realize real-time monitoring and data analysis of the production process. It helps to adjust production parameters in time and improve production efficiency.

02

Equipped with an automated control system, it can realize fully automatic production operations, improve production efficiency, and reduce labor costs

03

Use an imported lubrication system and shaft drive system. All components have reliable quality and stable performance.

04

Use wear-resistant materials. The support frame and aggregate bin are designed to be strong and durable for longer service life. The structural design is reasonable and the maintenance is gradual. Reduce downtime and increase production efficiency

05