For sites that require flexible relocation, we have designed a mobile crushing plant, which combines efficient crushing technology with convenient mobility and can quickly adapt to different work scenarios and improve operating efficiency.

SMAT mobile crushing plant has various configuration methods. SMAT provides free solution support. For customers in the Philippine market, the configuration of crusher equipment is very important. Appropriate production plans and high-quality crushers can not only ensure its production quality, but also reduce its failure rate and maintenance costs.

Hourly Capacity: 30-50 TPH

Maximum Feeding Size: 13.4″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 50-80 TPH

Maximum Feeding Size: 16.7″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 100-150 TPH

Maximum Feeding Size: 20″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

Hourly Capacity: 200-250 TPH

Maximum Feeding Size: 29.5″

Output Size: S1, 3/8, 3/4, G1

Power Supply: Electricity or Genset

| Solution | 30-50 TPH | 50-80 TPH | 100-150 TPH | 200-250 TPH |

| Maximum Feeding Size | 13.4’’ | 16.7’’ | 20’’ | 29.5’’ |

| Output Size | S1, 3/8, 3/4, G1 | |||

| Power Supply | Electricity or Genset | |||

With simple and firm structure, reliable operation, easy maintenance and service, and relatively low costs in production and construction, the SMAT jaw crusher is still widely used in coarse, medium, and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building materials, electricity, transportation, and other industries.

01

SMAT cone crusher is a kind of stone crusher machine applied for metallurgy, building, road construction, chemical engineering, etc. It is suitable for medium and fine crushing with the features of a high crushing ratio, high efficiency, low energy consumption, and uniform particle size.

02

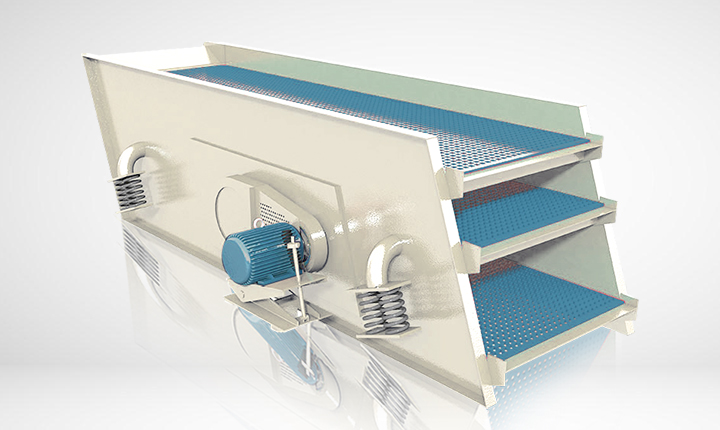

SMAT vibrating screen has high structural strength, simple maintenance, and long service life. Suitable for heavy, medium, and fine screening and other screening operations. The sieving machine is ideal for handling the products after primary and secondary crushing, as well as for inspection screening in the process and final product screening.

03

SMAT Crushing Plant in the Philippines

SMAT takes every order seriously. Every step of the process is checked by special person. Every important component is pre-tested before shipment, especially the mixer machine. It also ensures that free spare parts are given to the customer to avoid any possible accidents.

01

SMAT has nearly 30 years of export experience. The crushing plant manufactured by us have been exported to different countries. The Concrete Batching Plant will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

02

SMAT provides engineers with on-site installation guidance, commissioning, and training services. SMAT engineers have rich experience in mechanical, electrical, and civil engineering. Proficiency in English and Chinese, the common languages, ensures smooth communication with operators on site.

03

SMAT Mobile Crushing Plant in the Philippines

SMAT provides various concrete machine and crushing machine for your project.